Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

In this episode of The Engineering Commons, we discuss an electromechanical component commonly used to achieve physical motion; the ubiquitous direct-current (DC) motor.

In this episode of The Engineering Commons, we discuss an electromechanical component commonly used to achieve physical motion; the ubiquitous direct-current (DC) motor.

- Carmen admits to getting turned on by electricity… and sugar!

- Although differences between engines and motors can be argued, at least one definition claims that an engine converts chemical energy to mechanical energy, while a motor converts electrical energy to mechanical energy.

- DC motors are powered with direct current, while AC motors are powered with an alternating current.

- Carmen mentions an app note (pdf) on Brushless DC motors by MPS (Monolithic Power Systems).

- Although linear motors will not be covered in this episode, their operation is similar to that of rotational motors.

- The two major categories for DC motors are brushed and brushless; the two major categories for AC motors are synchronous and induction (asynchronous).

- When describing a motor’s mechanical components, the portion that rotates is the rotor, while the portion that remains stationary is the stator.

- Brian notes that Nikola Tesla’s induction motor may be his most significant invention.

- In induction motors, slip is percentage difference between the rotational speed of the magnetic field and that of the rotating shaft.

- A homopolar motor was developed by Michael Faraday in 1821.

- Joseph Henry created an electo-magnetic “rocker” in 1831.

- In 1832, William Sturgeon produced the first practical DC motor.

- An H-bridge is an electronic circuit that allows a DC motor to run forwards or backwards.

- In many cases, a pulse-width modulation (PWM) signal can be used to control motor speed. This is accomplished by turning motor power on and off at a high frequency, while maintaining a desired ratio of “on” time to “off” time.

- When describing a motor’s electrical components, the portion that carries the current is called the armature, while the portion that generates the magnetic flux is called the field.

- An electrical charge passing through a magnetic field is subject to a mechanical force, known as a Lorentz force. A conductor (wire) carrying current through a magnetic field can thus be levitated by this force.

- DC motor behavior is described by several motor constants, including the torque constant and the back-EMF constant.

- A commutator periodically reverse the flow of current through an external circuit. In a brushed DC motor, this is accomplished mechanically.

- Brushes deliver voltage to the commutator, and are often spring loaded against the commutator segments.

- In mechanical systems, rotational power is the product of torque and angular velocity.

- Brushless DC motors often use Hall effect sensors to detect when power should be switched to a different armature winding.

- A stepper motor advances by a fixed rotational angle each time it receives an input pulse.

- Enterprising engineers can play music with stepper motors!

Thanks to Les Chatfield for use of the photo titled “At speed!” Opening music by John Trimble, and concluding theme by Paul Stevenson.

Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

Brian, Carmen and Jeff discuss mechanical gears in this episode of The Engineering Commons.

Brian, Carmen and Jeff discuss mechanical gears in this episode of The Engineering Commons.

- Although a mechanical engineer, Jeff isn’t much for working on cars.

- We share a few stories about synchronizing generators, including use of a synchroscope.

- Brian mentions mechanisms with extremely high gear ratios.

- The two main functions of gears are trading off torque and speed, and reversing the direction of rotation.

- Spur gears are the most basic of mechanical gears.

- A spur gear profile is found in the Open Source Hardware Association logo.

- Carmen demonstrates his mastery of lyrics from the musical Grease.

- A commonsense explanation is provided by Jeff as to why gears need an integer number of teeth.

- If efficiency losses are ignored, ratios in the number of teeth between meshing spur gears provides the torque gain or rotational speed loss.

- Formula One racecar engines turn at very high rotational speeds.

- Gears are frequently used to increase the torque and decrease the speed of rotational actuators such as internal combustion engines or electric motors.

- A rack and pinion arrangement allows for converting between rotary and linear motion.

- Helical gears have curved teeth that allow for gradual tooth engagement, and they therefore run more quietly than spur gears.

- Bevel gears are often used to transfer power between shafts that are perpendicular to one another.

- Some basic gear set design considerations are detailed in the engineering information chapter of a Boston Gear product catalog.

- High gear ratios can be provided by a worm drive, but at the cost of lower mechanical efficiency.

- Planetary gear sets provide a great deal of flexibility, allowing for the merging of multiple torque inputs.

Thanks to William Warby for use of the photograph titled “Gears.” Opening music by John Trimble, and concluding theme by Paul Stevenson.

Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

Aeronautical engineer Clay Coons explains the most common types of engines, and why each type is optimal in certain applications.

Aeronautical engineer Clay Coons explains the most common types of engines, and why each type is optimal in certain applications.

- Antidisestablishmentarianism is the longest non-technical word in the English language.

- “Suck, squeeze, bang, blow” is a mnemonic phrase for remembering the stages for a 4-stroke engine.

- For engineers not dealing with computers or software, an engine generally refers to a device that performs mechanical work.

- Our guest for this episode is Clay Coons, who appeared on Episode 30 to talk about his travel adventures.

- Jeff asks about the difference between a motor and an engine. The most common answer relates to the source of input power.

- To be specific, we can talk about heat engines, which convert thermal energy to mechanical work.

- The three most commonly produced heat engines are spark-ignition, diesel, and jet engines.

- A number of different engines have been used to power aircraft.

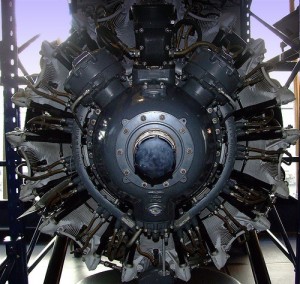

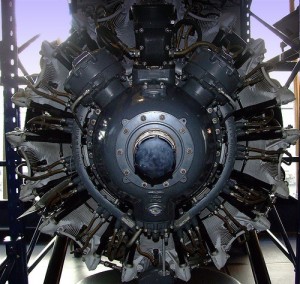

- A radial engine, which moves pistons radially outward from the drive shaft centerline, was frequently used in the early days of aviation (see episode photograph for an example).

- The “Mustang” P-51 fighter that saw action in World War II was powered by a water-cooled Packard V-12 (based on a Rolls-Royce Merlin engine).

- The cycles for a four-stroke spark-ignition engine are air intake (“suck”), air compression (“squeeze”), fuel combustion (“bang”), and exhaust evacuation (“blow”).

- A weed-wacker, or string trimmer, is a tool for cutting grass and plants, usually along sidewalks or garden borders.

- The ability of gasoline to resist ignition under compression is measured by its octane rating.

- Carmen makes reference to the television series Home Improvement, in which the main character was known to grunt occasionally.

- Clay explains that the reciprocating engine has remained a staple in automobiles for many years because it is reliable and economic to manufacture.

- In contrast to the reciprocation of a piston engine, a Wankel rotary engine uses a spinning Reuleaux-shaped triangle to produce the necessary compression of fuel and air.

- The Mazda RX-7 sports car famously used a Wankel engine.

- Chrysler tested a Turbine Car in the early 1960s.

- A Honeywell AGT1500 turbine engine is used to power the Abrams M-1 tank.

- Gas turbine engines have three core sections, each of which function continuously (in contrast to the discrete cycles of a reciprocating piston engine). These sections are known as the compressor, combustor, and turbine.

- Spinning blades at the front of a turbine engine, known as the compressor section, squeeze the intake air to make it more dense, thus providing more oxygen per unit volume.

- In the center of a turbine engine, the combustor mixes fuel with the compressed air, before igniting the mixture to release energy from the fuel.

- As the ignited fuel mixture rapidly expands in volume, the expanding gas rotates a set of blades known as the turbine section. These blades are connected to an axial shaft (turbine shaft) that, in turn, rotates the compressor section at the front of the engine.

- A jet engine is a gas turbine engine that uses energy from the exhaust gas to produce physical movement. Thus, a minimal amount of energy is put into rotating the turbine shaft, as the remainder is used to produce propulsive thrust.

- Jet engines use a nozzle to maximize the propulsive thrust that can be achieved from exiting combustion gases.

- A turboshaft engine is designed to maximize the amount of work that can be performed by the turbine shaft. Thus, every effort is made to maximize the efficiency of the turbine stage in recovering energy from the combustion gases and transferring it to an output power shaft.

- A supercharger is a mechanically-driven centrifugal air compressor driven by the crankshaft of a reciprocating-piston engine. Even at low speeds, it can effectively increase the density of air flowing into the engine cylinders.

- Exhaust gases spin the turbine of a turbocharger. A compressor, connected to the same shaft as the turbine, squeezes the incoming air to force additional oxygen into the engine.

- Jeff reminisces about his turbocharged four-cylinder 1984 Pontiac Sunbird.

- Due to their high thermal efficiency, diesel engines are preferred over gasoline engines for generating torque at lower speeds.

- Unlike a spark-ignition engine, a diesel engine does not add fuel until the piston is concluding its compressive stroke. The compression of the air/fuel mixture is sufficiently high to cause ignition, thus releasing energy from the fuel.

- A rocket engine is similar to a jet engine, but carries with it the oxidizer (normally oxygen) that is mixed with the fuel to allow combustion.

- The Centaur rocket stage was developed at NASA’s Lewis Research Center, where Clay once worked.

- Modern airliners use turbofan engines, which use turbine shaft power to accelerate intake air rearward, thus increasing engine thrust.

- Military aircraft use afterburners to generate a large amount of thrust, although this is not a very fuel efficient process.

- Carmen notes that the Porche Carrera GT had 10 cylinders, the Porche 917 had 12 cylinders, and a prototype 917 was tested with 16 cylinders.

- Carmen mentions getting parts from Harbor Freight Tools, a US retailer with the motto, “Quality Tools at Ridiculously Low Prices.”

- A conversation ensues about various types of torque wrenches.

- Clay mentions the car he had during his college years, a green 1975 Dodge Coronet.

- A water brake is a device that absorbs and measures shaft work.

- Jeff gets quizzed on the formula for converting torque to horsepower. Clay notes that $latex \text{HP} = (\tau\cdot\text{RPM}) / 5252$ when torque $latex \tau$ is measured in pound-feet. Jeff struggles to recall that 1 HP = 33,000 ft-lbs per minute.

- Clay reveals that his favorite beer is Caffrey’s Irish Ale.

- Carmen talks about a recent visit to Deschute’s Brewery in Portland, Oregon.

Thanks to Les Chatfield for his photograph titled “Pratt and Whitney power.” Podcast theme music by Paul Stevenson.

Practical insights for the engineering crowd

In this episode of The Engineering Commons, we discuss an electromechanical component commonly used to achieve physical motion; the ubiquitous direct-current (DC) motor.

In this episode of The Engineering Commons, we discuss an electromechanical component commonly used to achieve physical motion; the ubiquitous direct-current (DC) motor.