Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

In this episode of The Engineering Commons, we discuss engineering skills and duties learned in the workplace, rather than from a textbook.

In this episode of The Engineering Commons, we discuss engineering skills and duties learned in the workplace, rather than from a textbook.

- Brian tells young engineers that an engineering degree is a “learner’s permit.” Once in the workplace, engineers have to teach themselves to solve an entirely new class of problems.

- A gold-fish shaped retention pond, first mentioned by Adam in our episode on engineering pranks, is referenced once again, although your dutiful scribe is still looking for hard evidence of such a structure.

- An extended discussion related to beer production and consumption breaks out amongst the discussion panel.

- Jeff describes how the bricks that once covered the entire racing surface at the Indianapolis Motor Speedway are now found only at the start/finish line, in what is known as the Yard of Bricks.

- Lateral loading on racing surfaces, due to the massive grip exerted by race car tires, requires the use of specialized asphalt mixtures.

- Drivers in the Indianapolis 500 automobile race pull more than 3 lateral g’s while going through the turns.

- Quotes about the engineering profession:

“Engineering is the art of organizing and directing men, and of controlling the forces and materials of nature for the benefit of the human race.” — Henry Gordon Stott (1907)

“”The ideal engineer is a composite … He is not a scientist, he is not a mathematician, he is not a sociologist or a writer; but he may use the knowledge and techniques of any or all of these disciplines in solving engineering problems.” — N. W. Dougherty (1955)

“Engineering is not merely knowing and being knowledgeable, like a walking encyclopedia; engineering is not merely analysis; engineering is not merely the possession of the capacity to get elegant solutions to non-existent engineering problems; engineering is practicing the art of the organized forcing of technological change… Engineers operate at the interface between science and society…” — Gordon Stanley Brown (1962)

“Scientists study the world as it is, engineers create the world that never has been.” — Theodore von Kármán

- Engineers break complex problems into smaller solvable pieces. The “art” of engineering is knowing how big those pieces can be.

- Whereas textbook problems usually have a definite answer, problems from the workplace are often ill-defined, and may sometimes offer no practicable solution.

- Problem constraints in industry may seem at times arbitrary, being controlled by economic, political, and organizational powers beyond the engineer’s realm of influence. Additionally, these constraints are not fixed, but vary with time.

- We reveal our high-tech method of aligning audio tracks in Audacity, the audio editing software used to create this podcast.

- Obsolescence issues are increasingly important for design engineers as commercially-available components are being manufactured for shorter periods of time.

- Engineers must avoid the natural urge to over-design products, even when dealing with complex constraints.

- Making a prototype work once in the lab is far different than making thousands of mass-produced products work reliably in the field.

- An important part of an engineer’s job is prioritizing where one’s time should be spent.

- Many times it’s more important to be on the “proper” side of the equation than to be right; that is, one has to make certain assumptions that may be incorrect, but those assumptions need to be made such that the product or service will not fail, even if the assumptions are not perfectly accurate.

- Jeff’s example of a 500 ksi stress load would have been more realistic at 50 ksi or 500 MPa, at least for steel parts.

- In examining the meltdown of nuclear reactors at Japan’s Fukushima Nuclear Power Plant, recent reports have suggested that a contributing factor was the lowering of a seawall back in 1967.

- Jeff references a scene from The Big Bang Theory television show where Stuart and Sheldon argue about gradations of being wrong.

- It’s important for engineers to keep track of the small details, even though the process of doing so may be quite tedious.

- In his autobiography, test pilot Chuck Yeager recalls the tragic outcome of a line worker’s decision to install bolts “right side up” while assembling a jet plane aileron, even thought the blueprints indicated otherwise.

- Engineering designs need to account for human factors, as well as technical constraints and specifications.

- Jeff makes selective use of geometric dimensioning and tolerancing standards, as sometimes a simple callout works better in the prototype machine shop.

- As an engineer, skepticism is prudent in evaluating information and methods. However, too much skepticism can lead to one being labeled “not a team player.”

- Engineers are often asked to be “fortune tellers,” predicting future outcomes for processes and designs that have never before been realized.

- Adam emphasizes the importance of understanding safety factors, and their proper application in the design process.

- Production and maintenance costs are crucial factors in industry, while such cost issues are often overlooked in textbook problems.

Thanks to Seattle Municipal Archives for the photograph titled “Drafter working in Engineering Department, 1959.” Podcast theme music by Paul Stevenson.

Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

Adam leads the group on a discussion of project management in this episode of The Engineering Commons.

Adam leads the group on a discussion of project management in this episode of The Engineering Commons.

- Please help us improve the podcast by filling out our 2014 Listener Survey!

- Brian feels any technically interesting project is probably of sufficient complexity to require a project manager.

- Since Adam has a certificate in Project Management, he serves as our guide for this conversation.

- Adam refers to a book put out by the Project Management Institute (PMI), titled A Guide to the Project Management Body of Knowledge (PMBOK).

- A project is defined by the PMI as “a temporary group activity designed to produce a unique product, service or result.”

- Jeff wonders whether the company NeXT Computer would therefore have qualified as a project.

- Project that do something for the very first time can become “science projects,” placing unlimited demands on time and money. (With apologies to scientists, who find ways to live within their time and cost constraints ;^)

- Brian notes that engineers, when constructing complicated systems, rely heavily on solutions and technologies provided by vendors.

- Adam and Brian feel that the skills set needed to be a strong technical expert are fairly independent of those needed to be a good project manager.

- Carmen likes “take charge” project managers who quickly get down to business in meetings.

- Jeff mentions President Kennedy’s 1961 proclamation that the United States would send a man to the moon as an example of a leader who didn’t necessarily have strong technical skills, but Brian notes that Wernher von Braun’s engineering expertise was needed to make the project a success.

- A “strong matrix” organization allows project managers to easily pull resources from functional groups, while a “weak matrix” organization gives functional supervisors the authority to deny resources to project managers.

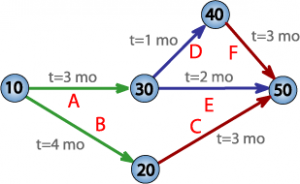

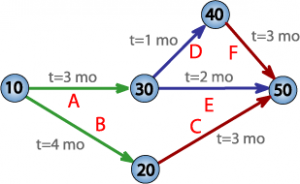

- Project managers have to balance the constraints of time, money, scope, and quality, as represented by the Project Management Triangle.

- A work breakdown structure decomposes a project into smaller tasks that can be carried out to ensure that the project is completed.

- Jeff notes the need to break personal tasks into smaller sub-tasks, such as a “next action,” when working with the Getting Things Done (GTD) method of time management.

- A lot of engineers first get introduced to working with a Gantt chart via the Microsoft Project software program.

- The “critical path” defines the series of events that have to occur on schedule for the project to be completed on time.

- With due credit to Donald Rumsfeld, Adam breaks risk into four categories: known knowns, known unknowns, unknown knowns, and unknown unknowns.

- Risk management methods include acceptance, mitigation, avoidance, and transference.

- Projects typically involve the five stages of initiation, planning, executing, monitoring and controlling, and closing.

- Jeff mentions the “not-invented-here” syndrome, which is an urge to repeatedly “reinvent the wheel.”

- A sturdy wooden gavel is handy for keeping meetings on task, says Carmen.

- According to the PMBOK, the common elements of project management systems are:

- Integration Management

- Scope Management

- Time Management

- Cost Management

- Quality Management

- Human Resource Management

- Communications Management

- Risk Management

- Procurement Management

- Stakeholders Management

Thanks to Wikipedia for the chart titled “Pert_chart_colored.” Podcast theme music provided by Paul Stevenson.

Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

This episode discusses similarities between engineers and accountants, and provides a brief overview of accounting terminology.

This episode discusses similarities between engineers and accountants, and provides a brief overview of accounting terminology.

- Like most engineers, Brian has gone through the process of assigning his engineering costs to a seemingly endless list of expense accounts.

- Accounting is an important function in virtually every business. Today’s episode considers some of the similarities between accounting and engineering.

- Accounting is the collection, organization, analysis, and presentation of financial records relating to an organization’s activities.

- Jeff references the text-to-speech cartoons generated online at xtranormal.com. Apparently, there’s a brief series of these videos dedicated to public accounting (foul language, NSFW).

- There is a difference between accounting and bookkeeping.

- In double-entry bookkeeping, the debits and credits always have to balance.

- The definitions of debit and credit have specific meanings for accountants that are different from the meanings commonly assigned in everyday usage.

- Financial transactions are recorded in ledgers, which may be one of five types: assets, liabilities, income, expenses, or equity. All the individual ledgers are combined to create the general ledger.

- Most financial statements are prepared in accordance with Generally Accepted Accounting Principles (GAAP).

- Accountants general adhere to the matching principle and the convention of conservatism.

- Financial years do not have to match up with the calendar year.

- Overly conservative estimates of project costs can have negative impacts on an organization’s financial planning.

- Accounting is carried out either on a cash basis or on an accrual basis.

- Billing and payment terms are often much different in industry than what household consumers are used to.

- Accounting activities are typically divided into financial and managerial accountancy.

- Financial reports for publicly traded companies in the United States can be found on the EDGAR website that is run by the Securities and Exchange Commission (SEC).

- Four common financial reports are the balance sheet, the income statement, the cash flow statement, and the statement of retained earnings.

- On a balance sheet, accountants must balance the equation Assets = Liabilities + Ownership Equity.

- A company’s value may exceed its net assets by an amount known as goodwill.

- Depreciation is a means for dealing with an asset’s reduction in value over time.

- Brian refers to the “We’ve fixed the glitch” scene from The Office.

- Costs can be either fixed or variable, and either direct or indirect.

- Indirect costs are often referred to as overhead. The precise method of overhead allocation is a managerial decision.

- Accountants also have to deal with the time value of money.

Thanks to SalFalko for the photo titled “business chart showing success.” Podcast theme music provided by Paul Stevenson

Practical insights for the engineering crowd

In this episode of The Engineering Commons, we discuss engineering skills and duties learned in the workplace, rather than from a textbook.

In this episode of The Engineering Commons, we discuss engineering skills and duties learned in the workplace, rather than from a textbook.