Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

Adam leads the group on a discussion of project management in this episode of The Engineering Commons.

Adam leads the group on a discussion of project management in this episode of The Engineering Commons.

- Please help us improve the podcast by filling out our 2014 Listener Survey!

- Brian feels any technically interesting project is probably of sufficient complexity to require a project manager.

- Since Adam has a certificate in Project Management, he serves as our guide for this conversation.

- Adam refers to a book put out by the Project Management Institute (PMI), titled A Guide to the Project Management Body of Knowledge (PMBOK).

- A project is defined by the PMI as “a temporary group activity designed to produce a unique product, service or result.”

- Jeff wonders whether the company NeXT Computer would therefore have qualified as a project.

- Project that do something for the very first time can become “science projects,” placing unlimited demands on time and money. (With apologies to scientists, who find ways to live within their time and cost constraints ;^)

- Brian notes that engineers, when constructing complicated systems, rely heavily on solutions and technologies provided by vendors.

- Adam and Brian feel that the skills set needed to be a strong technical expert are fairly independent of those needed to be a good project manager.

- Carmen likes “take charge” project managers who quickly get down to business in meetings.

- Jeff mentions President Kennedy’s 1961 proclamation that the United States would send a man to the moon as an example of a leader who didn’t necessarily have strong technical skills, but Brian notes that Wernher von Braun’s engineering expertise was needed to make the project a success.

- A “strong matrix” organization allows project managers to easily pull resources from functional groups, while a “weak matrix” organization gives functional supervisors the authority to deny resources to project managers.

- Project managers have to balance the constraints of time, money, scope, and quality, as represented by the Project Management Triangle.

- A work breakdown structure decomposes a project into smaller tasks that can be carried out to ensure that the project is completed.

- Jeff notes the need to break personal tasks into smaller sub-tasks, such as a “next action,” when working with the Getting Things Done (GTD) method of time management.

- A lot of engineers first get introduced to working with a Gantt chart via the Microsoft Project software program.

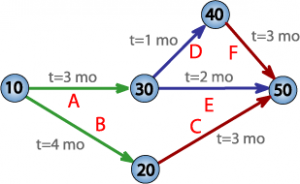

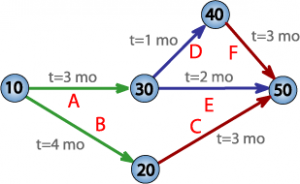

- The “critical path” defines the series of events that have to occur on schedule for the project to be completed on time.

- With due credit to Donald Rumsfeld, Adam breaks risk into four categories: known knowns, known unknowns, unknown knowns, and unknown unknowns.

- Risk management methods include acceptance, mitigation, avoidance, and transference.

- Projects typically involve the five stages of initiation, planning, executing, monitoring and controlling, and closing.

- Jeff mentions the “not-invented-here” syndrome, which is an urge to repeatedly “reinvent the wheel.”

- A sturdy wooden gavel is handy for keeping meetings on task, says Carmen.

- According to the PMBOK, the common elements of project management systems are:

- Integration Management

- Scope Management

- Time Management

- Cost Management

- Quality Management

- Human Resource Management

- Communications Management

- Risk Management

- Procurement Management

- Stakeholders Management

Thanks to Wikipedia for the chart titled “Pert_chart_colored.” Podcast theme music provided by Paul Stevenson.

Podcast: Play in new window | Download

Subscribe: Apple Podcasts |

Guest Erica Lee Garcia explains the role of process improvement tools such as Six Sigma, Lean Manufacturing, and Statistical Process Control in this episode of The Engineering Commons podcast.

Guest Erica Lee Garcia explains the role of process improvement tools such as Six Sigma, Lean Manufacturing, and Statistical Process Control in this episode of The Engineering Commons podcast.

- Although process improvement tools are widely used in manufacturing, not all engineers are familiar with their usage.

- Our guest is Erica Lee Garcia, a Professional Engineer from Canada, who is also the owner and CEO of Erica Lee Consulting.

- One might have expected Erica to go into civil or mechanical engineering based on her childhood activities.

- Erica majored in Materials and Metallurgical Engineering at Queen’s University in Kingston, Ontario.

- Our guest started her career working for a firm that produced powdered metal products.

- In trying to determine why conveyer belts kept breaking in a sintering furnace, Erica got her first exposure to the continuous improvement process.

- Six sigma is all about getting rid of variation, while the lean method is all about getting rid of waste.

- Statistical process control (SPC) is a control scheme used for process analysis and monitoring.

- Kaizen refers to a philosophy focused on continuous process improvement. The term has recently come to mean a concentrated effort in dealing with a particular issue over a short period of time; such an activity may also be referred to as a “kaizen blitz” or “kaizen event.”

- Dr. Jeffrey Liker, a professor of industrial engineering from the University of Michigan, published The Toyota Way in 2003. The book details 14 principles that provide the framework for Toyota’s continual improvement system.

- The Kaizen Institute and the American Society for Quality are organizations that promote the continuous improvement of people, processes, and systems.

- Erica has run into situations where engineers and accountants have wildly differing interpretations of the same underlying data.

- Adam asks how projects can continue to improve after all the “low-hanging fruit” has already been gathered.

- Bruce Tuckman introduced the “Forming — Storming — Norming — Performing” model of group development in 1965.

- The phases of a Six Sigma project are “Define — Measure — Analyze — Improve — Control,” also known as DMAIC, for short.

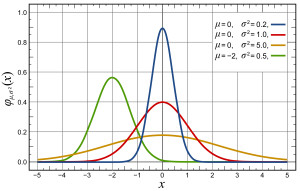

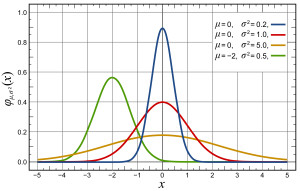

- Erica addresses how one might deal with non-normal data while engaging in process improvement.

- Process variations are designated as resulting from “common” and “special” causes.

- Jeff notes that the 2007 financial crisis has been partially blamed on fat-tailed distributions that were distinctly different from assumed Gaussian probabilities.

- Erica mentions a video presentation by Dan Milstein talking about the 5 Whys, a tool used in process improvement to determine cause and effect relationships.

- Brian inquires about the minimum production volumes required to justify initiating a continuous improvement project.

- Jeff raises the notion that Six Sigma may kill innovation. That position is refuted by Erica, who notes that there is a method of Design for Six Sigma.

- While the United States celebrates National Engineering Week for seven days in February, the entire month of March is set aside as National Engineering Month in Canada.

- Our guest believes that aspiration messaging is more effective than descriptions of day-to-day duties when undertaking engineering outreach.

- The Changing the Conversation campaign, sponsored by the National Academy of Engineering, is mentioned by Erica. She notes a video from the site, titled “If it weren’t hard, it wouldn’t be engineering.”

- Advice for early- and mid-career engineers is provided by Erica on her website, EngineerYourLife.net.

- Marc Garneau is a Candadian engineer, astronaut, and politician.

- Brian comments that engineering is a “world of niches,” in which engineers often have radically different duties and assignments, even if working in the same discipline, or for the same company.

- Erica can be found on Twitter as @engineeryrlife. She can also be contacted via her website.

Thanks to Wikimedia Commons for the graph of a normal distribution probability density function. Podcast theme music provided by Paul Stevenson

Practical insights for the engineering crowd

Adam leads the group on a discussion of project management in this episode of The Engineering Commons.

Adam leads the group on a discussion of project management in this episode of The Engineering Commons.